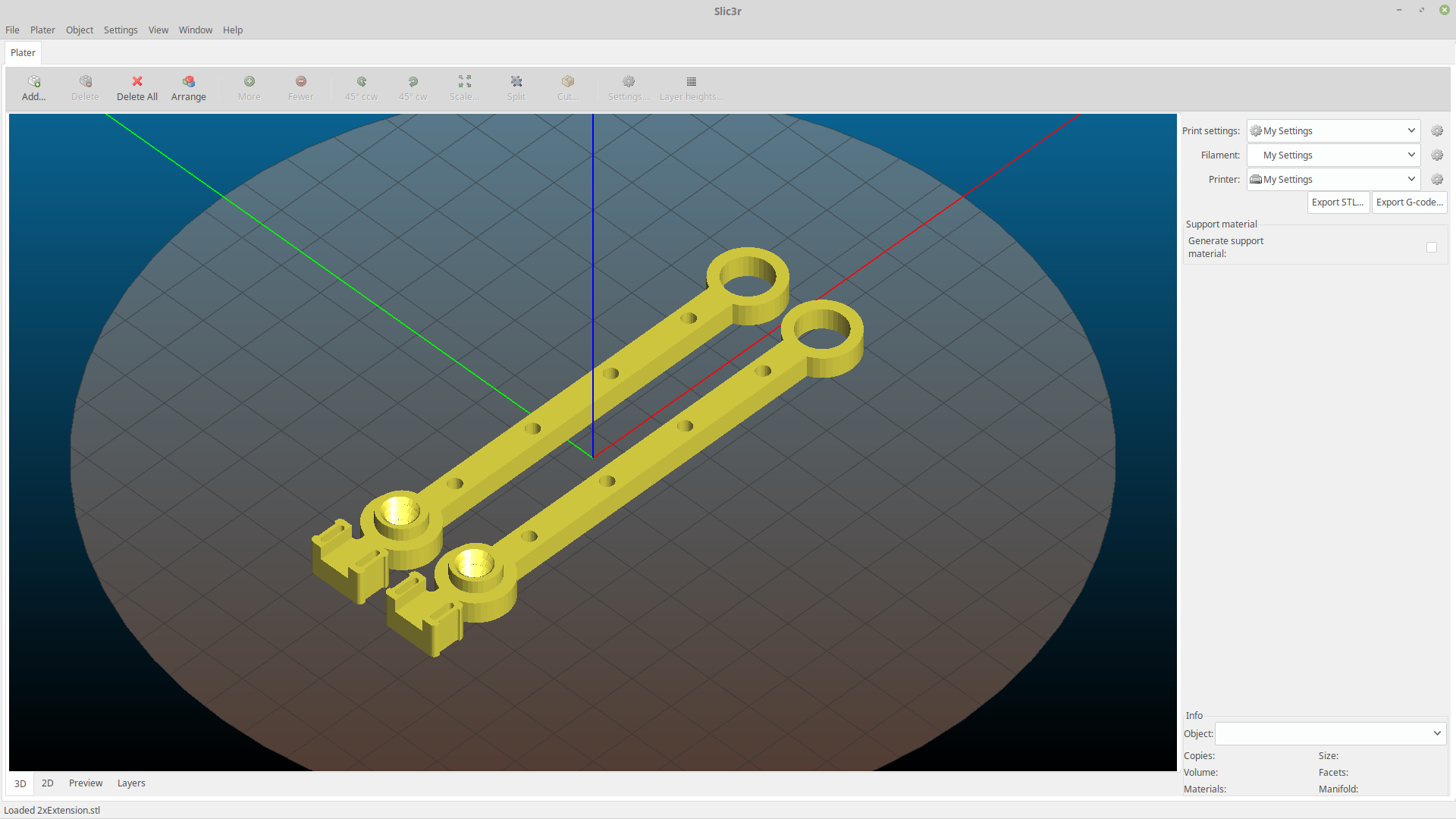

Slic3r is a Gcode generator that can be used with a variety of firmware and CNC machine type.

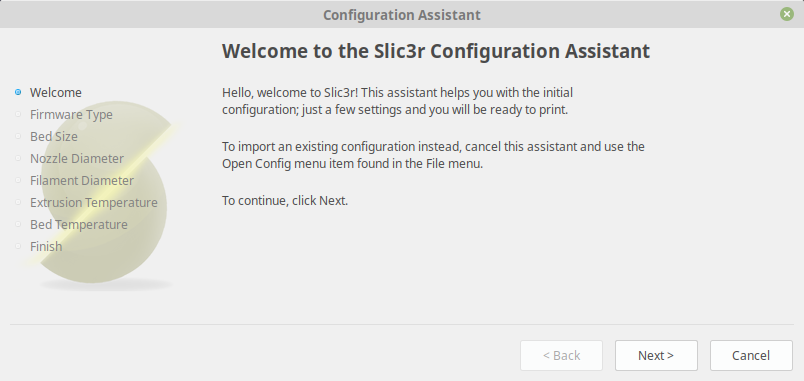

When you start out with Slic3 you will be presented with a configuration wizard. I found the wizard to be straighforward and easy to add my printer. It was however necessary to restart my edition of Slic3r to get the printer configuration to show.

If you know your printer well you should be able to walk right through this.

Slicing

As soon as you load your object Slic3r creates the Layers you can view them with the Layers Tab down at the bottom.

Sli3r supports more than just .Stl, it has native suppor for Obj, Amf and 3mf

Print Preview

The Print Preview shows a relatively accurate render of how the print will come out. A well-rendered preview can highlight a model with issues. Notice the surface of the larger end. This is a case where the thickness is not even divisible by the nozzle width.

Favorite Features

Automatic Re-Centering. With other Slicers I spend a noticable amount of time centering my prints. I use a Delta print and it prints the best right in the middle. Slic3r takes care of this without a thought.

Split. Breaking down a platter into its constituent components can be a cumbersome click intensive process. Sli3r accomplishes this with a single click. I love it.

Printing

Although this is consider a Slic3r it has the ability to send a print job to a printer via serial connection or software like Octoprint. I have tried Octoprint in the past but have been unable or without suffivient patience to see it through. As I timep this sentence I am getting a mostly succesful print using Slic3r to Octoprint. If that holds true I am fully sold.